Description :

The transformer’s operating principle is based on Faraday’s law of electromagnetic induction. Electrical energy received by the primary circuit is converted into magnetic energy, generated flux flows through the closed magnetic circuit & the magnetic energy is reconverted into electrical energy in the secondary electrical circuit.

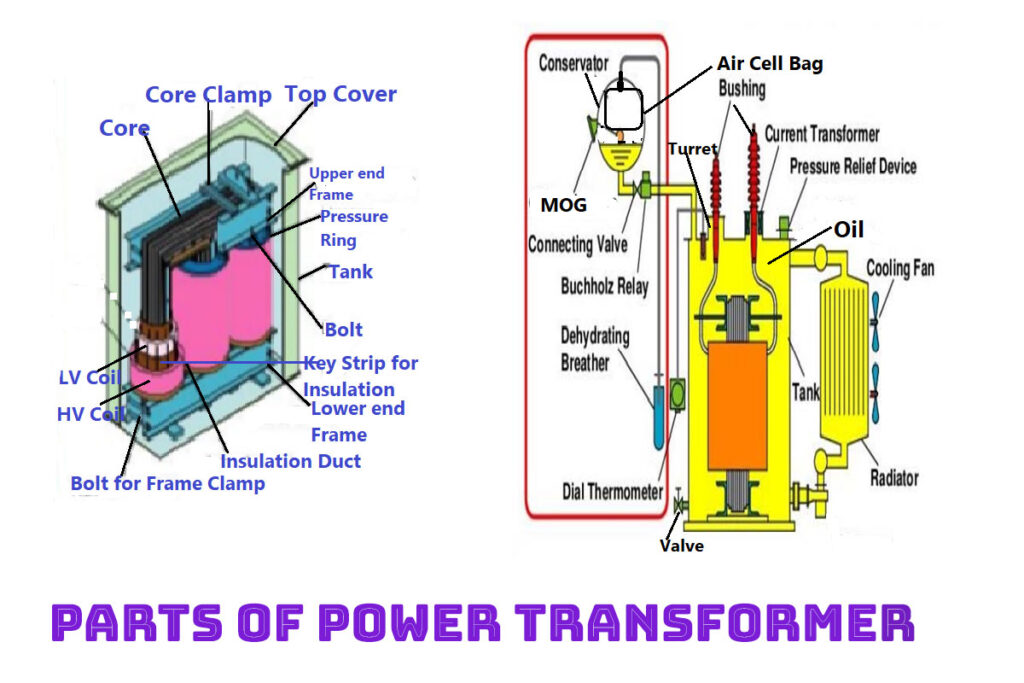

To attain the overall function of the transformer, it consists of different parts where each part does its function by own way.

Power transformer composes of the following components:

1. Core

Transformer core is used for the magnetic circuit & to support the windings. It is made of soft iron which should have a low reluctance to the magnetic flux as the flux is inversely proportional to the reluctance. The core should be laminated & about 3% silicon (Si ) is added in Fe in order to reduce eddy current loss and hysteresis loss which is called iron loss / no-load loss.

(** In the upcoming post, I will discuss in detail the power transformer core.)

2. Winding

Primary & secondary windings, both separately consist of several turns that are connected in series (to form coil). In small rated transformers, windings might be of the aluminum conductor due to their significant cost advantage over copper. In a Power transformer, the copper conductor is used for winding design. Commonly used paper covered Cu conductor can be of individual rectangle strip, bunch, or CTC (Continuously Transposed Cable). No of turns & size (area) of the windings depends on the voltage & current. High voltage winding has more turns & thinner (small area) conductors than low voltage winding (it consists of fewer turns & thick Cu conductor due to low voltage and more current respectively).

(** I will write in detail regarding the power transformer windings in a future post.)

3. Insulating Materials

Insulation design is the heart of the transformer, particularly in power transformer. Insulation space influences the cost of the transformer. Papers & press boards (made of wood pulp) are used as insulating materials that are cellulose in nature. Cellulose is a plyometric material of cellobiose. These papers & pressboards, a thick insulating paper provide insulation/isolation between turn to turn, core to winding, winding to winding, high voltage leads to ground. Insulating paper & pressboard should have high electrical & mechanical strength while being used in the transformer.

(** I will write in detail regarding insulation of power transformer in a future post.)

4. Transformer Oil

Transformer oil acts as insulation as well as a cooling medium by transferring heat from inside the transformer. It is one of the vital parts that affect the performance. It produced by refining petroleum oil. But due to a very high flash point (about 140 deg C), good thermal conductivity & high dielectric strength, it is used in transformer.

5. Tank & Radiators

The active part, the core-coil assembly of the transformer is placed inside the transformer tank. It is filled with oil for cooling & insulation purposes, so it should be leakproof. The tank is made of MS sheets.

The radiator is used to dissipate heat produced in the transformer by way of radiation or convection. Tank body can dissipate loss as heat at a rate of 500 watts/sqm of the tank surface area. If the total loss exceeds the heat dissipation capacity of the tank surface, the excess loss is dissipated by the radiators. Radiators are made of CRCA steel sheets. Pressed steel radiator & corrugated wall panel radiator are most commonly used. Power transformer uses pressed steel type.

6. Bushings

Bushings are used for terminating windings on the tank body to connect the transformer with the external lines. It insulates the conductor from the tank body & made of porcelain. Bushings are selected based on voltage class as well as the rated current of the transformer.

7. Tap Changer

Tap changers are used to control the output voltage variations. Tap changers are two types. 1. Off- load tap changer is used after disconnecting the transformer. 2. But in the case of on-load tap changer tapings are changed to control voltage without disconnecting the transformer from the supply. Power transformer uses on-load, auto tap changer.

8. Conservator

The conservator tank is a metallic, cylindrical, air-free drum that is placed above the transformer main tank. It is a container of transformer oil. Normally half of the drum is filled with oil & allows the oil to expand & contract as the temperature varies. It is connected to the oil-filled main tank inside the transformer through the pipeline & at the top vented to the atmosphere through the air-cell bag in case of the power transformer.

9. Buchholz Relay

Buchholz relay is a protective device that is used in oil-immersed power transformers. This safety device is placed on the path of the pipeline, between the main tank & conservator. It has multiple methods to detect a failing transformer, a type of gas & oil actuated protection relay. When fault like a breakdown of insulating oil or insulation failure of winding turns to occur inside the transformer, it generates excessive heat & therefore decomposes the oil which results in the formation of gas. Gas bubbles tend to flow towards the conservator & are collected in the Buchholz relay. If accumulated gas exceeds a certain limit or oil flow rapidly into the conservator, float switches (alarm or trip) operate accordingly, either alarm is generated or disconnect the transformer from the supply.

10. PRD (Pressure Relief Device)

Pressure Relief Device is a safety device & normally mounted on the top cover of the oil-immersed power transformer. It is used to release excessive internal oil pressure developed inside the transformer due to internal fault. If the internal oil pressure is developed and exceeds the pre-set pressure limit, then the pressure relief valve (spring type) opens, rapidly releases the internal pressure until it becomes normal. Then it comes back to its original position. PRD is fitted with an alarm/trip switch to disconnect the transformer from the supply.

11. Lightning Arrester

Lightning Arrester/Surge Arrester is used for the protection of the transformer against the lightning surge that travels along the line. It is installed in the transformer tank. The most common surge arresters are non-linear metal oxide resistors type in porcelain or silicone rubber housing and are fitted in parallel with the transformer and connected to the earth. Lightning arrester bypasses the abnormal high voltage to the earth without affecting the continuity of supply. The arrestor provides a conducting path to the surge waves of relatively low impedance between the line and the earth.

12. Breather

Breather is used in the oil-immersed transformer attached to the conservator. It serves as the breathing point of the transformer. Silica gel breather is fitted with a slight glass so that the color of the silica gel crystals is visible. Breathers filter out the moisture from the air, absorbing moisture by silica gel. The color changes from blue to pink as the crystals absorb moisture. When the crystal became saturated with moisture, they should be reactivated.

13. Air Cell Bag

Air cell is used in power transformer. It is fitted inside the conservator, isolating the transformer oil from the atmosphere. Thus preventing contamination of atmospheric gases or moisture with the transformer oil. When temperature rises & the oil expands into the conservator, the floating air cell bag moves upward & air releases from the bag, and vice versa.

14. OTI & WTI

Oil Temperature Indicator (OTI) indicates top oil temperature at an instant of time & loading cycle. It acts as a caution gauge for high oil temperature. OTI is fitted with an alarm and trip contacts. They operated when the temperature of top oil exceeds the permissible limit.

Similarly, Winding Temperature Indicator (WTI) with alarm & trip contacts is also a transformer accessory for protecting the power transformer against high winding temperature.

15. MOG

Magnetic oil level gauge is used to indicate the level of the transformer insulating oil inside the conservator. MOG with a low oil level alarm is a common instrument for protecting the power transformer against low oil level.

16. Oil Surge Relay

Protective device, Oil Surge Relay (OSR) is used to protect the on-load tap changer (OLTC) against abnormal conditions developed inside it. OSR is fitted on the oil pipeline between the OLTC tank & OLTC conservator. When oil flow from OLTC exceeds the specified limit, the tripping circuit activates, thus the power transformer becomes turnoff & protects the OLTC.

17. CT

Current Transformers (CTs) are used in power transformers for measuring & protection purposes. They are placed inside the turret around the HT & LT bushings. CT is an instrument transformer, designed to produce an alternating current in its secondary winding that is proportional to the current that it is measuring in its primary.